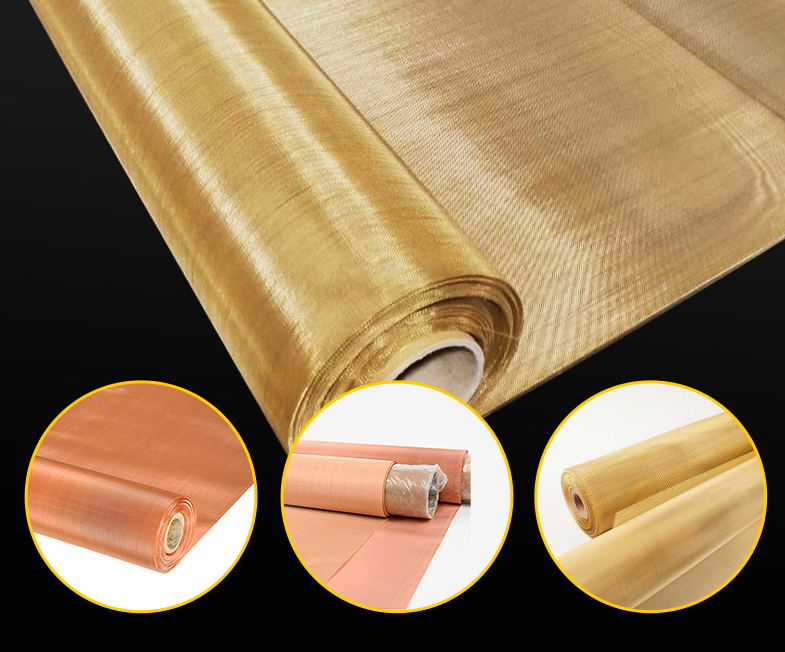

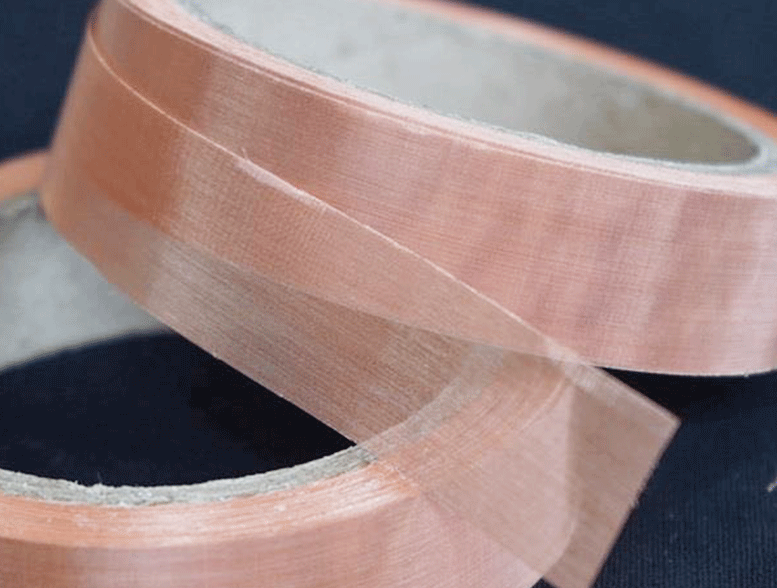

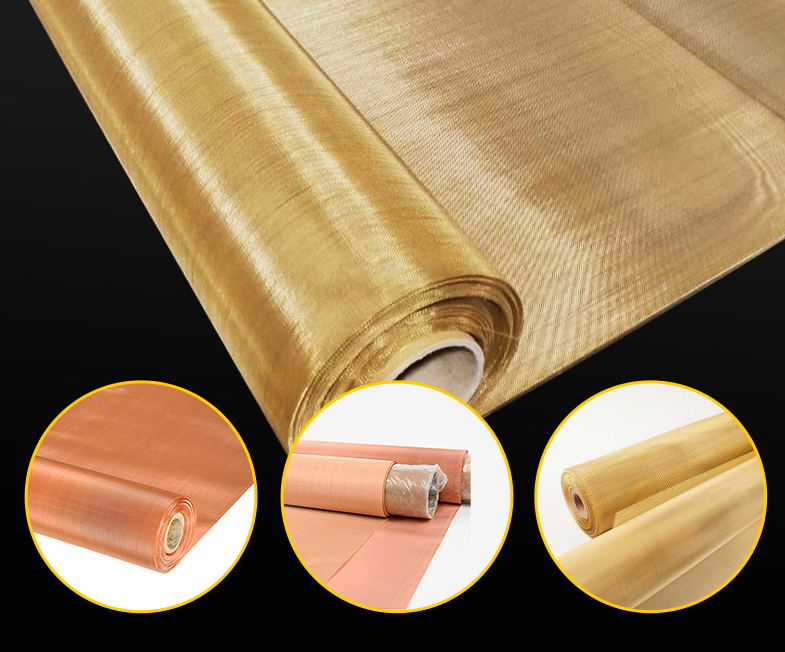

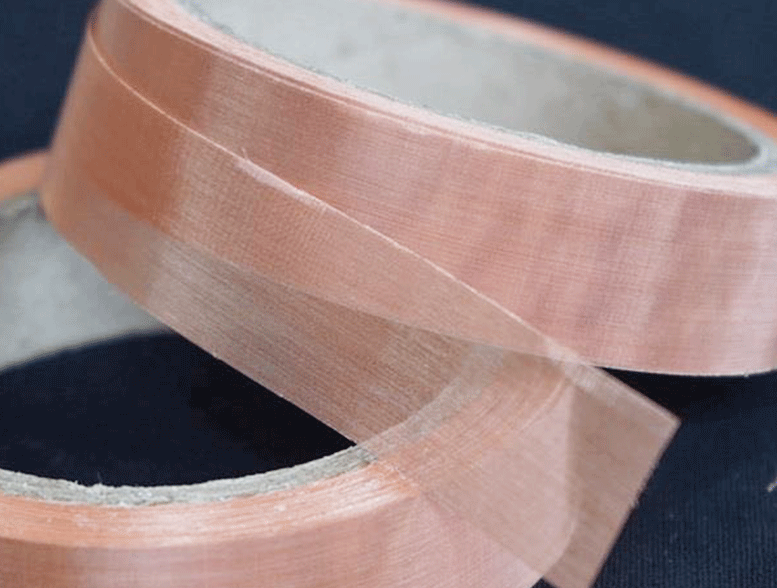

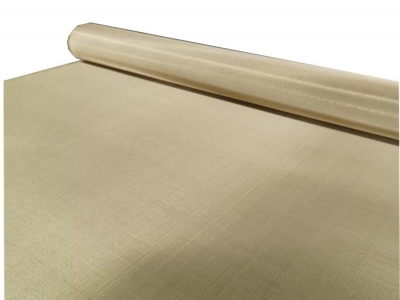

High-Purity Copper & Phosphor Bronze Mesh - Precision Filter Screen with Anti-Static, RF Shielding, Conductive Heat Dissipation

Product Overview

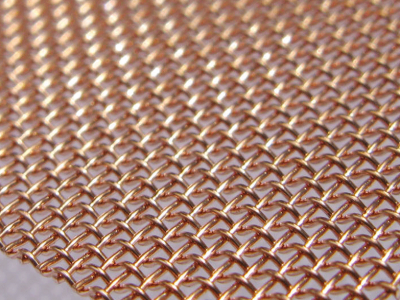

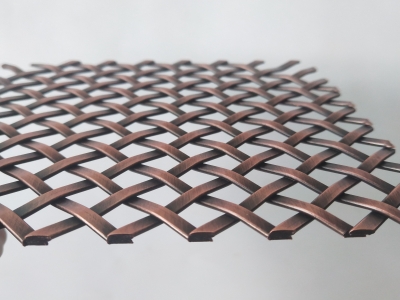

Our electrostatically shielded copper meshes are engineered for critical industrial applications requiring precision filtration, electromagnetic interference (EMI) suppression, and thermal management. Crafted from oxygen-free C10100 pure copper (99.99% Cu) and C51900 phosphor bronze alloys, these meshes deliver unmatched electrical conductivity (≥98% IACS), corrosion resistance, and mechanical durability. Ideal for aerospace, electronics manufacturing, laboratory equipment, and telecommunications infrastructure.

Key Technical Specifications

| Parameter | Pure Copper Mesh | Phosphor Bronze Mesh |

|---|

| Material Standard | ASTM B152 C10100 | ASTM B103 C51900 |

| Conductivity | ≥100% IACS at 20°C | ≥22% IACS at 20°C |

| Thermal Conductivity | 398 W/m·K | 109 W/m·K |

| Tensile Strength | 210-310 MPa | 550-690 MPa |

| Operating Temp | -200°C to +250°C | -196°C to +200°C |

| Surface Resistivity | <0.1 Ω/sq | <0.5 Ω/sq |

| Shielding Effectiveness | 60-100 dB (10MHz-10GHz) | 45-85 dB (10MHz-10GHz) |

| Mesh Options | 10-500 mesh | 20-400 mesh |

| Wire Diameter | 0.03mm - 2.0mm | 0.05mm - 1.5mm |

Core Functional Advantages

1. Electrostatic Dissipation (ESD Protection)

Surface resistance <10<sup>3</sup> Ω ensures static charge neutralization in explosive environments (ATEX/IECEx compliance)

Prevents component damage during semiconductor handling or pharmaceutical powder processing

2. EMI/RFI Shielding Performance

3. Precision Filtration Capabilities

Tolerance: ±3μm for micron-grade separation

Chemical resistance: Withstands acids, alkalis, and organic solvents (pH 3-11)

Applications:

▸ Fuel cell catalyst recovery

▸ High-purity chemical sieving

▸ Food-grade oil filtration (FDA/EC1935 compliant)

4. Thermal Management Properties

Material Selection Guide

| Application Scenario | Recommended Material | Rationale |

|---|

| Ultra-high vacuum systems | OFHC Copper | Outgassing rate <10<sup>-9</sup> Torr·L/sec/cm² |

| Wear-resistant sieving | Phosphor Bronze | 20% higher hardness than pure copper |

| Cryogenic environments | C10100 Copper | Maintains ductility at -196°C |

| Marine corrosion zones | Tin-plated Bronze | Salt spray resistance >1000 hrs |

Customization Services

Weaving patterns: Plain weave, twill weave, Dutch weave

Edge finishing: Ultrasonic welding, hemmed borders, flange mounting

Surface treatments: Electropolishing, nickel plating, passivation

Dimensional tailoring: Custom panel sizes up to 3m × 10m, cylindrical cages

Compliance & Certifications

Typical Industrial Use Cases

• Particle accelerator beamline collimators (CERN specification)

• EMI gasketing for aircraft avionics (DO-160G compliant)

• Electrochemical reactor current collectors

• Cleanroom HEPA filter reinforcement

• RF test chamber ventilation windows

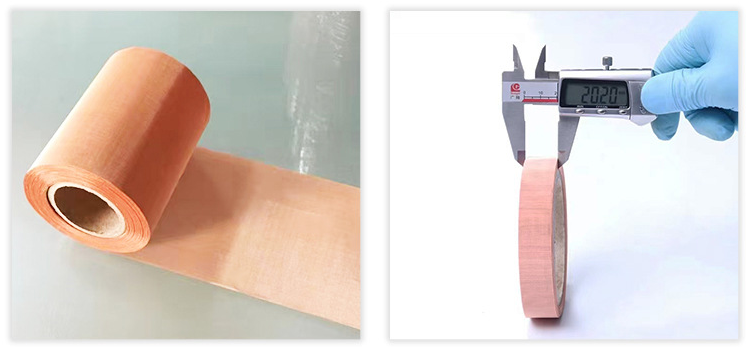

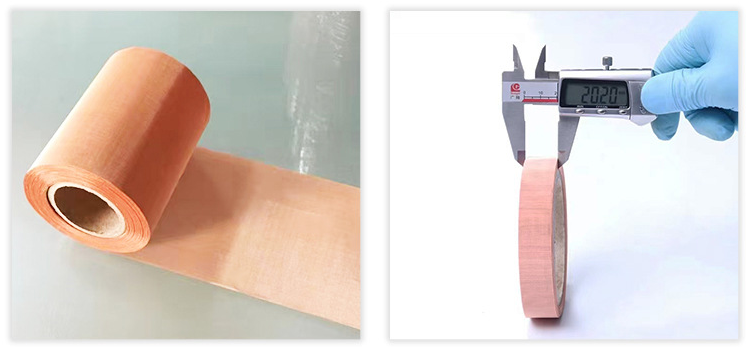

Ordering Information

Specify:

Alloy type (C10100 / C51900)

Mesh count (lines per inch/cm)

Wire diameter (mm)

Dimensions (L × W × Thickness)

Surface treatment (if required)

Export Packaging

VCI-coated waterproof kraft paper

Edge-protected plywood crates

ESD-safe sealed containers

Humidity indicator cards included

.jpg)